News

The world of moulds

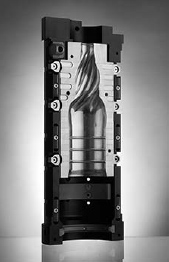

The thousands of products created over all these years are the confirmation of the technology and skill we have developed in the blow moulding industry and of the recognition we have received throughout the world.

The thousands of products created over all these years are the confirmation of the technology and skill we have developed in the blow moulding industry and of the recognition we have received throughout the world. DEMO tries to give every project an original and personalized hallmark in order to meet the demands and expectations of its clients.

Quality and precision

The aluminium and steel we use to create our moulds are provided exclusively by certified suppliers and are processed with machine tools that have been in production for approximately four years. All of this to guarantee efficiency and precision in all processing stages, even the most complex. As far as the software we use is concerned, we are constantly updating. The CAD/CAM programme we use has been updated to the 2018 version, which adds up to a reduction in processing time in comparison with the past and ensures prompt delivery to our clients.

Innovation

We were one of the first companies in Europe to develop moulds for major blow moulding machines with “Quick Change” insert technology which makes it possible for us to customize containers with made-to-order logos and incisions. This system also allows us to use a single mould to manufacture differently shaped containers, resulting in a sizeable reduction in terms of cost and time.

But that’s not all. Since DEMO always focuses on combining innovation and reduced costs, it has also developed specific solutions for manufacturing bottle bottoms with considerably less compressed air. In fact, our technology makes it possible for us to blow bottle bottoms with much less air in comparison to the commonly used standards.